The Age of Shims

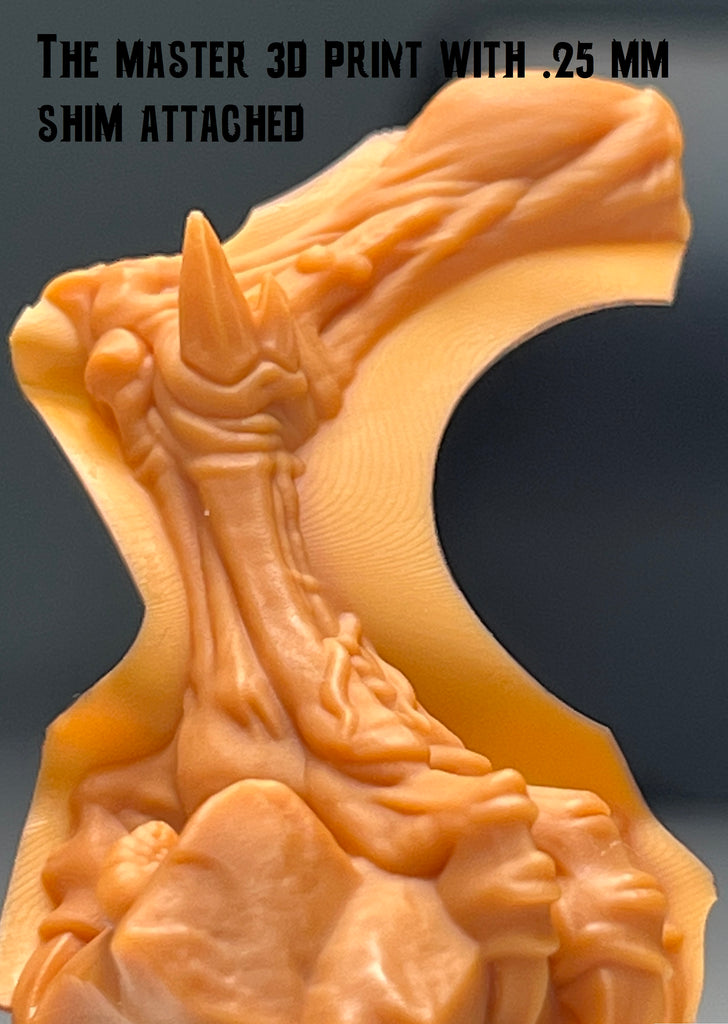

As the person responsible for the quality of the resin miniatures you receive, I wanted to share a recent change in our workflow; we are now using shims to improve the quality of our miniatures. Some of our recent models near the end of 2022 have this technique applied. This may look unsightly upon initial inspection, as they bear a resemblance to flash, but in practice this should allow our supporters to obtain a nicer finish.

What is a shim in the context of resin models?

It is a thin piece of material used to align parts, make them fit, or reduce mold wear. At a glance, it might look a lot like flash (excess plastic forced between facing surfaces as two halves of a mold close up) due to its placement between molds, however it has been very carefully thought out and placed to offer optimum support. Almost all of the "shims" are .25mm in thickness. That is the thinnest we can 3D print something while keeping it stable enough to work with. This also generally becomes thinner during the casting process due to pressure.

What are the pros and cons?

- You will benefit the most from this change if you are a hobbyist that cares about mold lines and would like to see Creature Caster do more exotic designs.

- I feel there will be a portion of the hobbyist community that will dislike this change. I would expect people who generally do not clean mold lines (and people who are more focused on playing instead of painting) will find that the work has increased to assemble their models.

It has been a dilemma to decide if we should make this change or go with what we've done in the past. We have mulled over this for many years, wondering if we should make what we believe is a positive change or go with what has been working well enough. Our logic is that our supporters have bought the models as centerpieces and our team wants to provide the experience to best achieve the polished look of a premium model by using our shim technique.

The WHYS.

No longer need to sand our miniatures, thus safer

It seems that very few hobbyists sand models and prefer to only use a hobby knife to prep their parts. Shims provide the opportunity to obtain a great finish without having to sand. Sanding releases small particulates into the air which is a health hazard, particularly if proper PPE is not worn.

Less work for people who care about mold lines

It is easier to remove material than to add material. It saves a lot of time when you don’t have to fill areas where the two halves of the mold come together or shave away material to level the mold line (which can greatly distort the shape of the part).

Allows us to create evocative designs while keeping the parts to a reasonable quantity

Resin Casting follows certain Design principles. We must follow the Rules of Resin Casting (which we have honed over the years) in order to create quality pieces and consistent molds. Certain shims allow us to circumvent these rules and allow us to make complex models with less parts, sharper points, and deeper undercuts. An example of something shims lets us do is the sharp feathers that are unfurled in many directions on our Smengal model. It allows us to make complex shapes with fewer parts. For example, without shims, we have never been able to make the individual feathers flip out in different directions since those wayward feathers would snap the resin or rip the silicone while demolding. The other option without shims would require us to make those feathers separate pieces (increasing the number of parts) or simply just making the wing flat and losing that dynamism.

Shims absorb mold shifts.

A mold shift is caused by a misalignment of the two halves of the mold resulting in a mold line which is difficult to realign with just a knife (think two tectonic plates pushing against each other). Generally you have to fill and sand to obtain a nice finish. One reason for this shifting is due to chemical shrinkage of the materials used in casting. Larger molds could be more prone to this type of shifting due to the amount of materials used. Another reason for a shift is an uneven application of pressure (due to difficult control factors) to the two halves of the mold coming together. For example, smooth rounded areas (such as human-like thighs) are especially prone to shifting.

a mold shift on a rounded surface which is difficult to remove without first leveling the shift with some sandable filler

Our team makes great efforts to place mold lines on areas which will result in the least amount of cleaning and distortion. However, there are times when there are very few good options but to place the mold line over an area that we would normally like to avoid. The shim over this area will help absorb excess pressure and prevent the model from having a misalignment.

Our team is always working to make the experience with our models better. Another example of this, which hasn’t been made public, is that we make sure that there is no mold release in our workflow. It is messy for you and for us and we are willing to lose some production to provide a better experience while working with resin. So, if a hobbyist does not wash our models thoroughly, it is unlikely that their paint and primer will not stick (a common issue that comes with mold release). I still recommend making sure that the surface is free of dust and oils (fingerprints) if you decide to primer coat your model or before you put your first coats of paint on; doing so will help to avoid the primer coat collecting dust and oils as well.

In Closing

We have used shims in the past with difficult designs, but the extensive use of them in the 3D space is a recent addition to our workflow and there will be times when our team might make less than perfect choices when applying this method. We use all our experience and passion to make these choices and there are also other necessities in production that use shimming to improve the casting experience.

All these efforts are for one primary purpose: you will be proud of the work you put into assembling and painting our range of miniatures and will be able to avoid as many cons of working with resin as possible while enjoying the benefits of striking and life-like details. From our experience, many hobbyists may initially find the shims annoying. Beginners might not even understand what the hell is going on. Our instincts say that people dislike change, and we might get some flak for this change. We are hoping that people will notice the quality ceiling of their finished models will be higher and easier to achieve, and will appreciate this change as much as we do. This guide was to help hobbyists understand our reasons behind it. We are open to your feedback, good or bad, to help us make your future experiences with us good ones. Message (support@creaturecaster.com) with any questions or feedback regarding your experiences, or message us on our social media.

Paint Sets

-

Mindwork Heavy Body Acrylics - Brom Signature Palette

Regular price $124.99 CADRegular priceUnit price per -

Mindwork Heavy Body Acrylics - Primary Set

Regular price $49.99 CADRegular priceUnit price per